NXTPLAST – Introduction

NXTPLAST Ready Mix Plaster is a ready mix cement plaster with high quality polymer additives to substitute for the traditional site mix wall plaster process. The solutionconsists ofprocessed sand which is graded and distributed as per particle size and proportionately mixed, cement and water soluble polymers which act as additives. The application method requires mixing of water before application and the mix is ready for plastering NXTPLAST Ready Mix Plaster can be used for both external and internal plastering.

NXTPLAST Ready Mix Plaster can be applied on:

- AAC Block Walls

- Clay Brick Walls

- Fly Ash Block Walls

- Stone Walls

- Concrete Block Walls

- Concrete Surfaces

PLASTER COATS

Internal: 10-15 mm single coat is recommended for internal plaster covering.

External: Two coats are recommended to cover the external side of walls i.e. Base coat of 8-12 mm and Finish cost of 8-12 mm to get a total thickness of around 18-20 mm, Further depending upon site conditions. After the Base coat minimum of 2 to 3 days curing must be done before the application of the final coat.

COMPARISON

| PERFORMANCE PARAMETERS | JOB-SITE PLASTER | NXTPLAST |

|---|---|---|

| DE-BONDING LOSSES | High | Negligible |

| SMOOTHNESS | Not so smooth | Smooth and hard surface provides aesthetic base of plaster to work upon. |

| CRACK FORMATION | Due to on site mixing practice, chances of crack formation is more. | NXTPLAST produced at automated dry mix plant. Chances of crack formation is very negligible subjected to proper curing and application. |

| WATER: CEMENT RATIO | Due to presence of moisture in sand it is not possible to deter- mine exact quantity of water to be mixed. | Due to dry sand used, water cement ratio is easily maintained and full strength of plaster is obtained. |

| GRADING OF SAND | No grading | NXTPLAST has graded sand which results compactness of plaster. |

| CEMENT: SAND RATIO | Mistake may occur at job site mix | Sand cement ratio is maintained as NXTPLAST is made in automated plant. |

| POLYMER MODIFICATION | Polymer modification difficult as it involves multiple polymers and doses. | Polymers already added, results in overall durability. |

FEATURES & BENEFITS NXTPLAST

High Strength

High compressive and tensile strength increases masonry strength and load-bearing capacity.

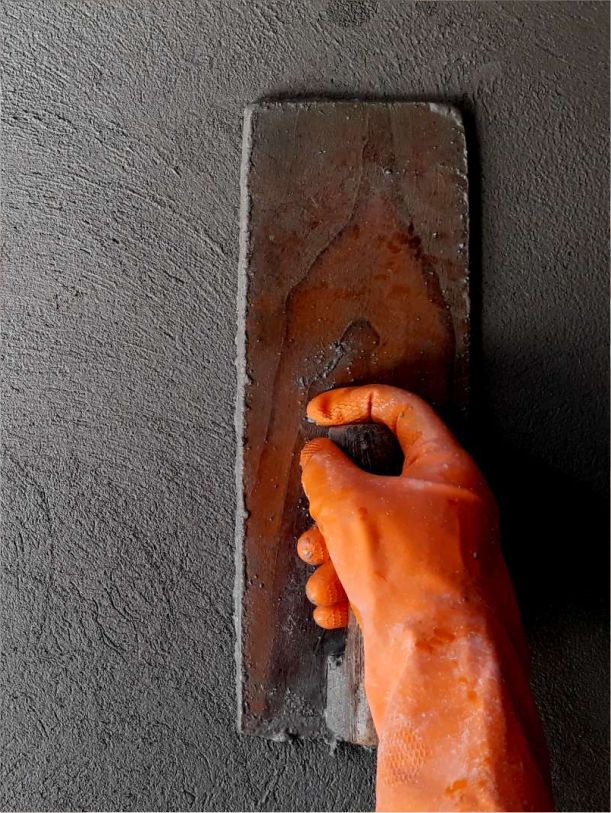

Easy Application

The material is pre-mixed and only water has to be added on site. This makes the process of plastering much easier and quicker.

Minimum Cracks

Shrinkage cracks are minimised as premix plaster raw materials are tested and accurately mixed with specific particle size and quantity.

Higher Coverage

Due to lower density and high volume, it covers 15-20 sq.ft./bag with a thickness of 10-12mm.

Storage

Easy to maintain stock as equal size packaging in bag form is provided.

Finish

Surface finish after application is excellent and equal due to best particle size grading, hence maximizing wall plaster performance.

Economical

It provides smooth finish walls even in a single coat. Hence saves time and cost required for putty coating.

Availability

Unlike the uncertain availability of raw river sand, premix bags are available round the year.

Minimum Wastage

The wastage caused in the conventional site mix process while sand sieving and mixing material is totally avoided.

Premixed

No site mix and blending of powder is required. Only water is to be added.

Consistency

Due to the manufacturing process and accurate particle size distribution, the premix bags are of consistent quality.

| Parameters | Values |

|---|---|

| Appearance | Greyish Granular Powder |

| Coverage | 17 to 20 square feet / 40 Kg bag @ 10-12 mm thickness |

| Thickness of Single Layer | 6-12 mm |

| Pot Life | Approx 1-2 hours @ 27° C |

| Water Demand | 17-20% of Mix (can vary on climatic conditions) |

| Bulk Density | 1.2-1.6 Kg/litre unit |

| Compressive Strength (MPa) | More than 4 in 28 days |